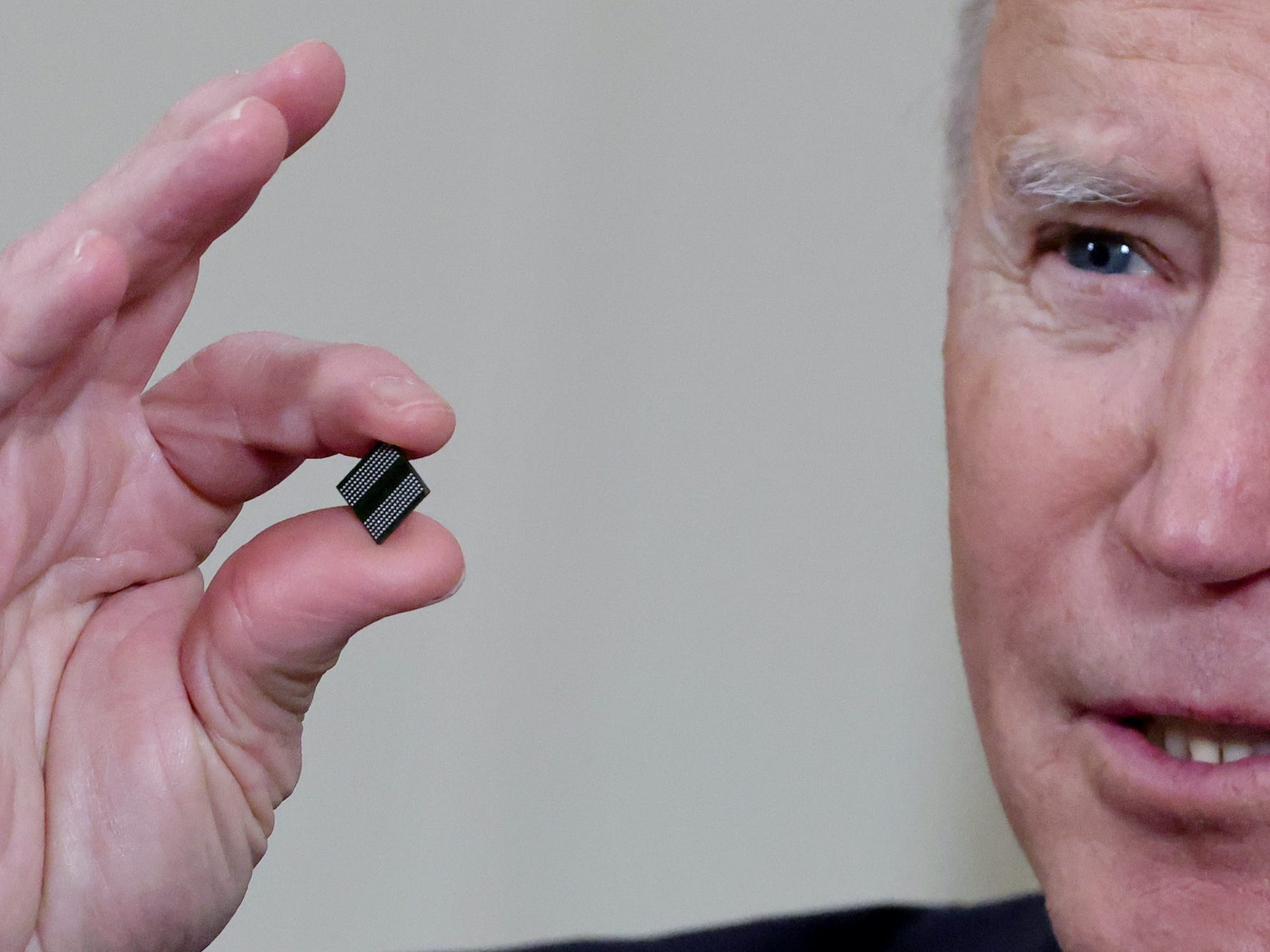

Jonathan Ernst/Reuters

- The US relies heavily on outsourcing chip-making since it's cheaper and easier to go overseas.

- The country's reliance on foreign manufacturers is even more glaring amid the global chip shortage.

- The solution, as President Biden has said, is to invest in domestic chip production.

- See more stories on Insider's business page.

A crushing computer chip shortage continues to choke the global supply chain.

Automakers are producing vehicles without smart technology – which requires chips – Apple's MacBook and iPad production was reportedly delayed, and PlayStation 5s are being produced in limited amounts due to the squeeze.

It's an effect caused over time by pandemic-driven shutdowns and soaring demand for products that need chips.

But one question that has emerged during the crisis is where chips are produced – and why the US doesn't manufacture much of the global supply.

Here's why it doesn't.

Chips are difficult to produce, and it's cheaper for US companies to outsource

In 1990, the US produced 37% of the world's chip supply, according to a September 2020 report from the Semiconductor Industry Association. But now, the country is responsible for just 12% of global chip production.

Seventy-five percent of the world's chip manufacturing comes out of Asia, per the report, and China is positioned to become the largest chip producer by 2030.

Why the decline in the US? It became cheaper to build chip facilities in countries outside of the US. Those foreign governments offer more attractive financial incentives to construct semiconductor factories, like tax breaks and grants. There's also less regulation in places like Asia. On top of that, there aren't as many jobs in the US created to run such high-tech factories.

There was a recent attempt to do so under the Trump administration - Apple supplier Foxconn was slated to build a Wisconsin facility that would produce large-screen TV displays and said it would create 13,000 jobs, but the whole project never panned out.

Andy Manis/Getty Images

Some of the country's largest chip manufacturers are also some of the biggest in the world. Intel still produces much of its chip supply at home, as the Wall Street Journal reported. But other major US chip producers outsource manufacturing to companies in Asia due to costs. One of those foreign contract companies is Taiwan Semiconductor Manufacturing Company, which produces more than half of the world's computer chips and is also Apple's primary supplier.

Making computer chips is a complex process. It's also difficult and expensive to build new facilities to manufacture the vital silicon component, which means companies have to rely on existing plants. A new semiconductor factory can cost up to $20 billion, as ON Semiconductor CEO Keith Jackson wrote in Fortune, and that price tag is much higher in the US.

There are economic and national security benefits to ramping up US chip production

There could be risks in depending on foreign chipmakers if the US continues to fall behind China in the chip race, as the Journal notes.

President Joe Biden is aware of the issue and the threats posed by relying too heavily on foreign manufacturing. As part of Biden's $2 trillion infrastructure plan, there's a $50 billion allotment for domestic chip manufacturing incentives.

In a Monday meeting, Biden said the key to navigating the current chip shortage crisis is to invest in the country's chip production.

"We need to build the infrastructure of today and not repair the one of yesterday," Biden said, according to NBC News. "The plan I propose will protect our supply chain and revitalize American manufacturing."

But as Recode notes, it won't be a simple task to transition reliance to homegrown chip production. There will be a handful of factors to consider over time, like weaning off of foreign contract manufacturers and ensuring there are enough US workers to power new facilities.